Do you feel that you are facing the following challenges in production management?

Challenges in Production Planning and Output Value Analysis

Inaccurate demand forecasting and imbalanced resource allocation lead to low production efficiency and high costs.

Low Efficiency in Continuous Improvement Proposals

The cumbersome proposal process and inefficient information synchronization hinder the implementation of measures.

Long Production Order Delivery Cycles

Unreasonable production planning and insufficient application of information technology lead to long delivery cycles.

Inadequate Monitoring of Employee Working Hours

Lack of scientific scheduling leads to the inability to deliver orders on time.

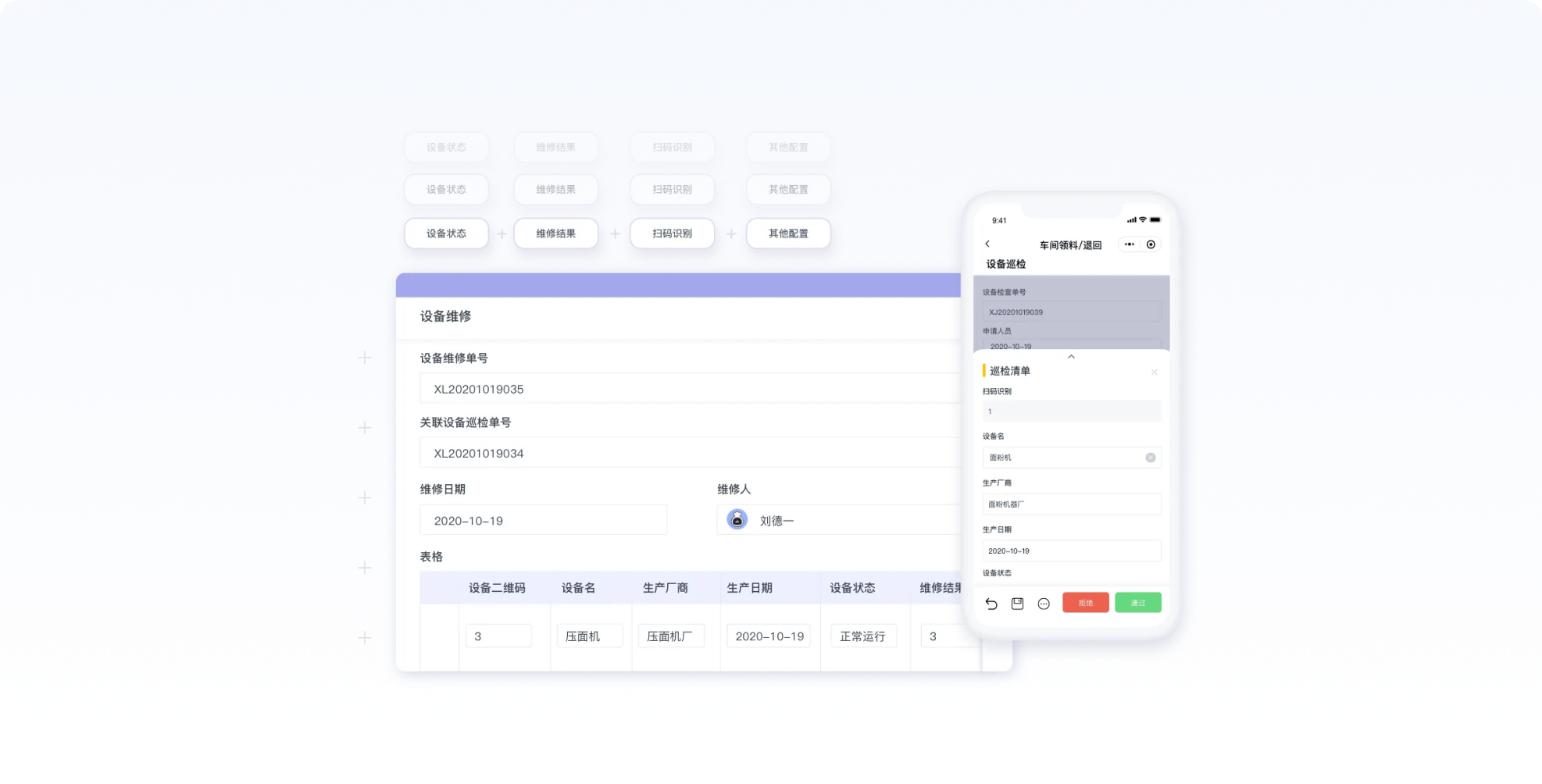

Inefficient Equipment Control and Management

Lack of a real-time monitoring system and reliance on manual inspections can lead to delayed responses or missed inspections.

Intelligent Management System

01

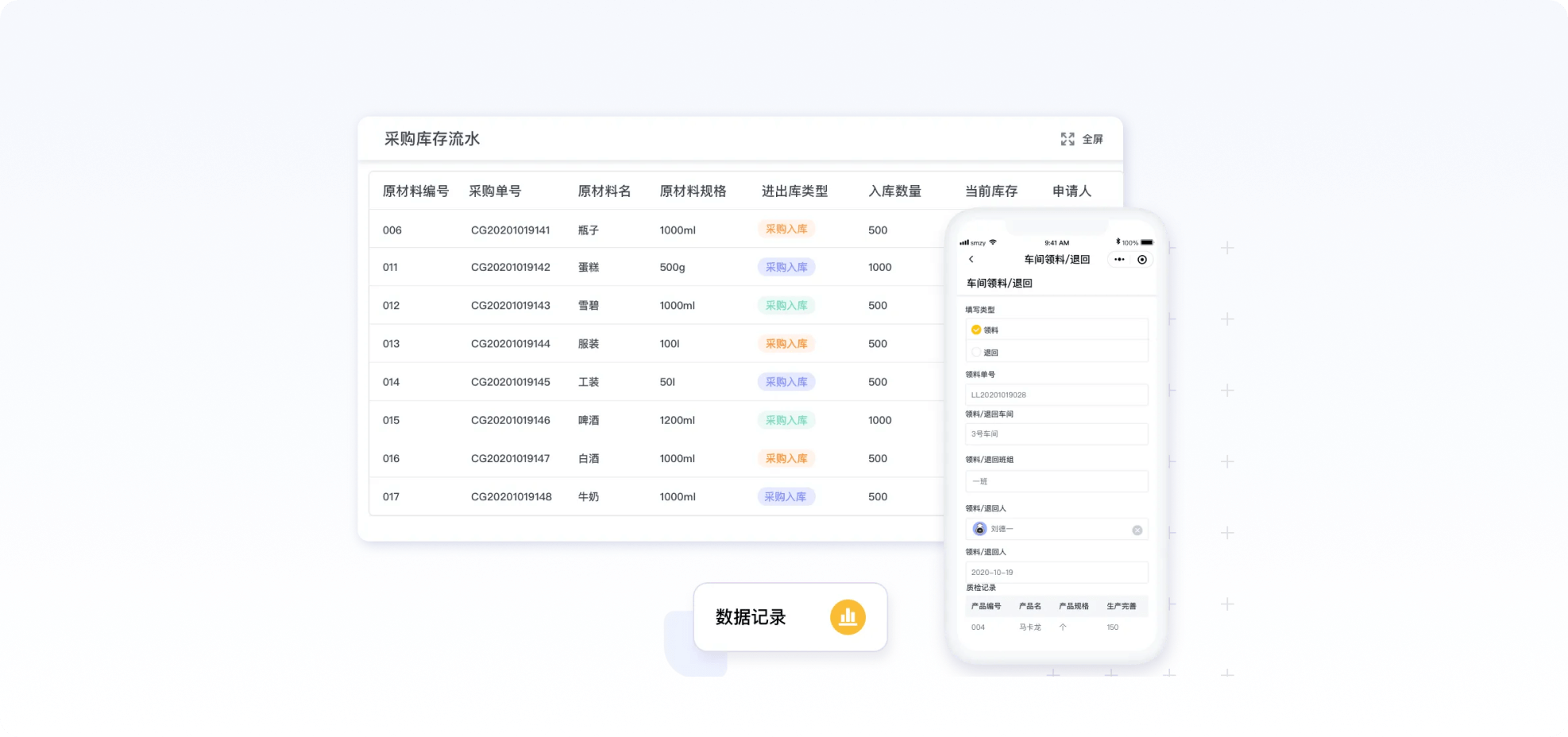

Standardized and Precise Production Database

Establishing a database with a unified format reduces data errors and simplifies the processes of data maintenance and updates.

02

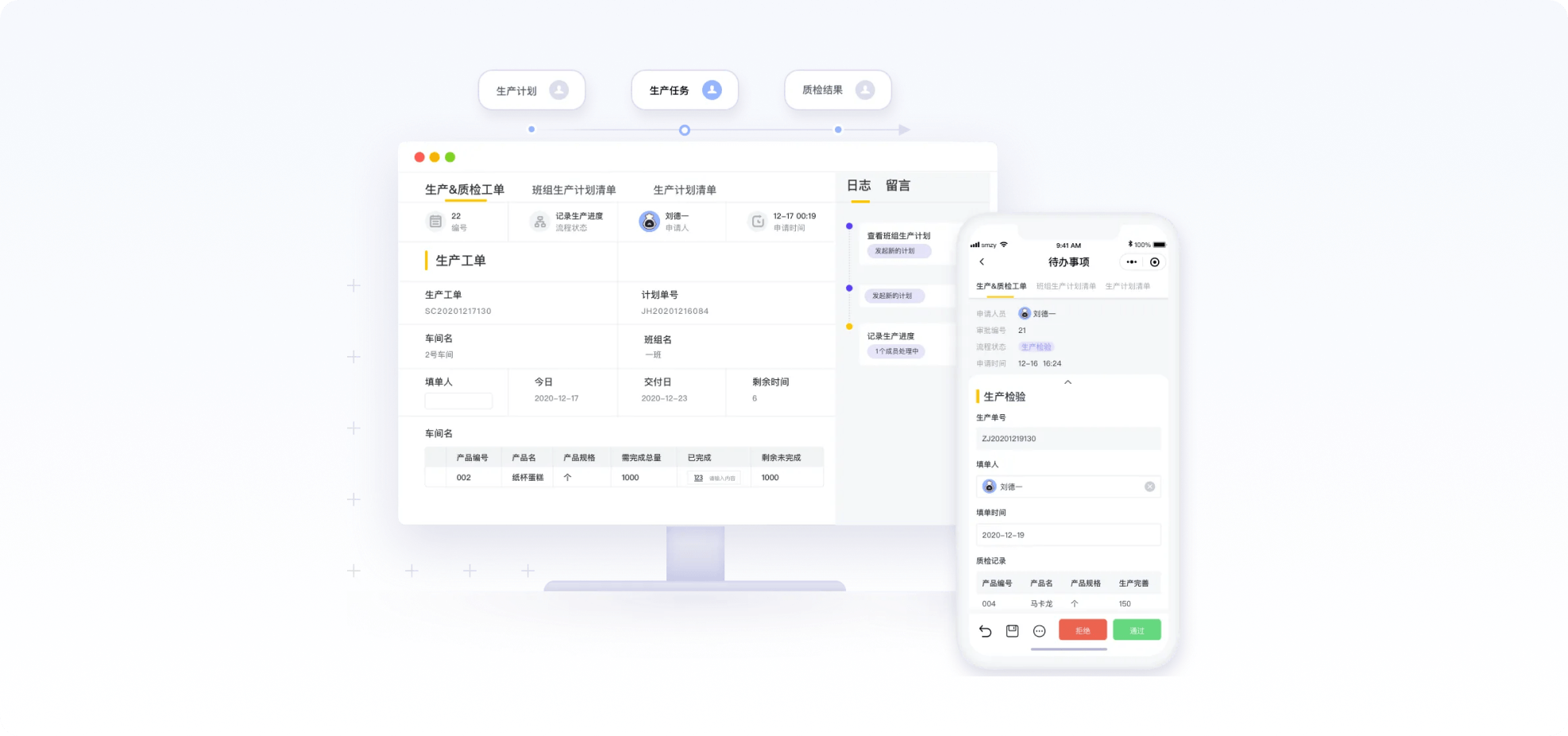

Data Traceability and Production Process Control

Recording detailed production information enables rapid tracking of product batches and real-time monitoring of the production process to ensure compliance with quality standards.

03

Increased Production Efficiency

Utilizing precise data to optimize production planning and allocate resources rationally reduces unnecessary waiting and waste, thereby increasing overall production speed.

04

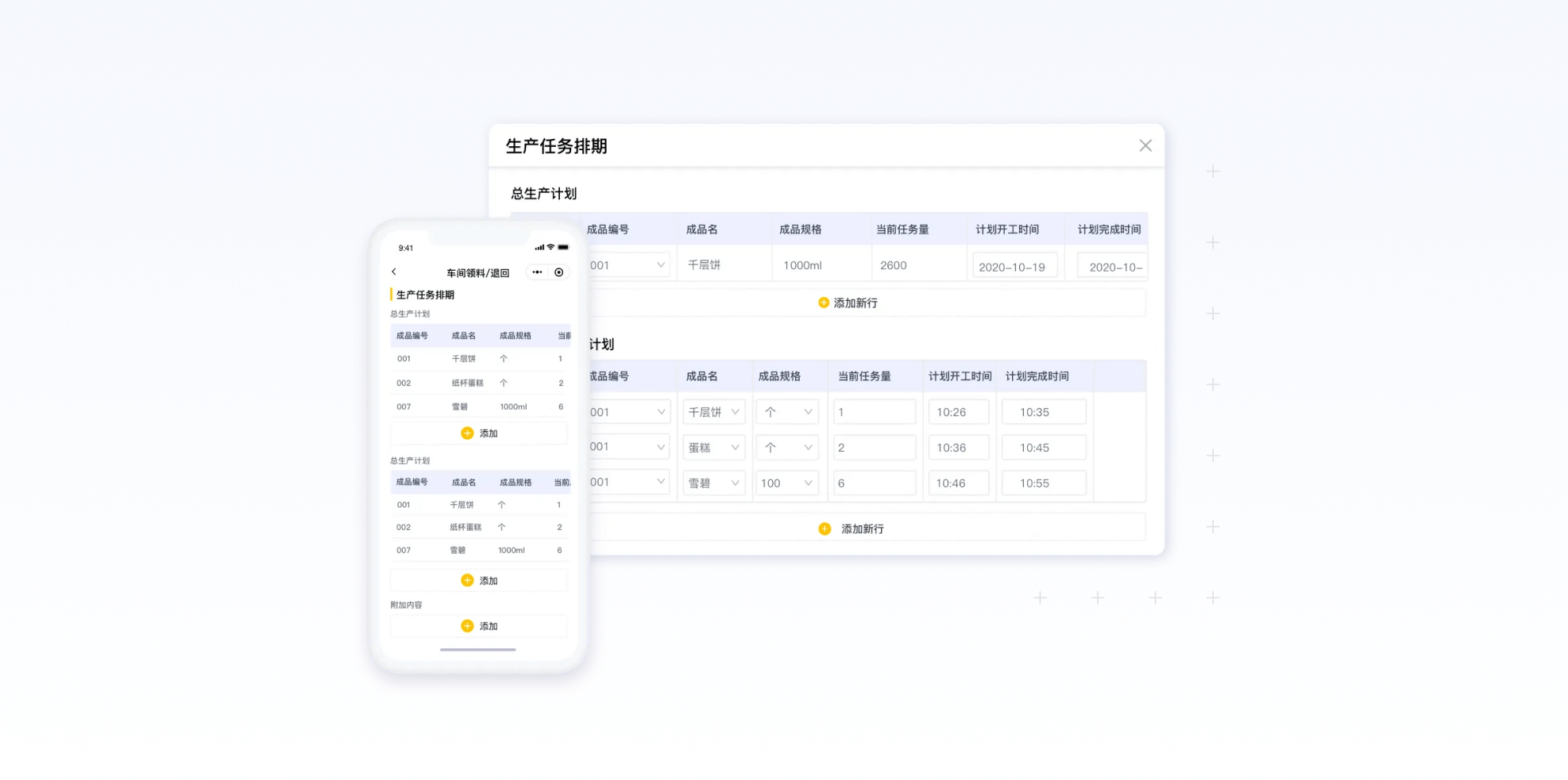

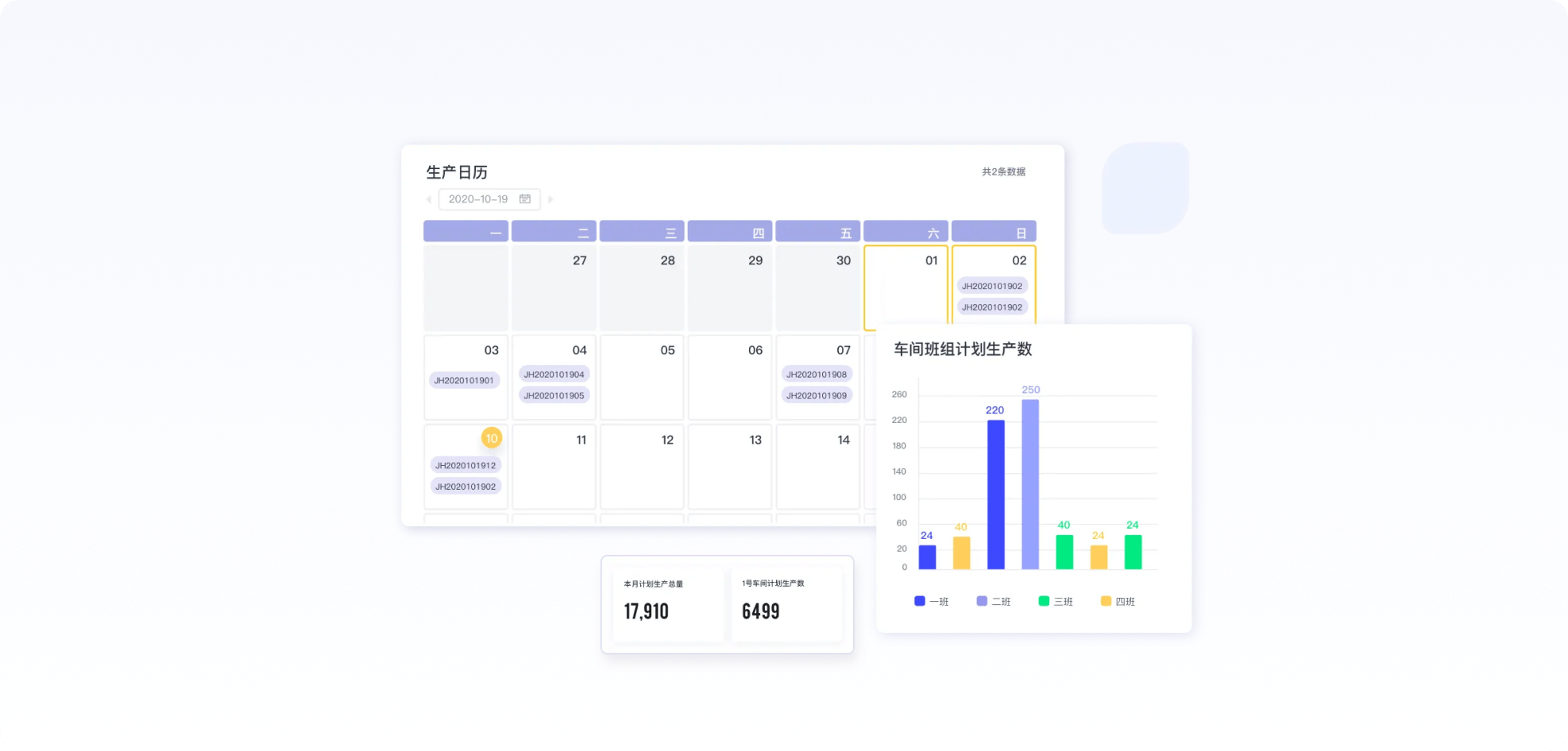

Simple Interface and Easy Operation

Providing an intuitive and user-friendly interface, simplifying the operation process, enabling users to quickly get started, access the required information rapidly, and accelerate decision-making.

05

Superior Performance and Convenience

The system responds quickly to user operations, integrates multiple functions such as orders, inventory, and production scheduling, and also supports mobile devices, allowing managers to keep track of production status at any time.

06

Stable and Reliable, Ensuring Production Safety

Ensuring the system operates stably over long periods, taking strict measures to protect data security, and ensuring the production process complies with laws and regulations to reduce compliance risks.

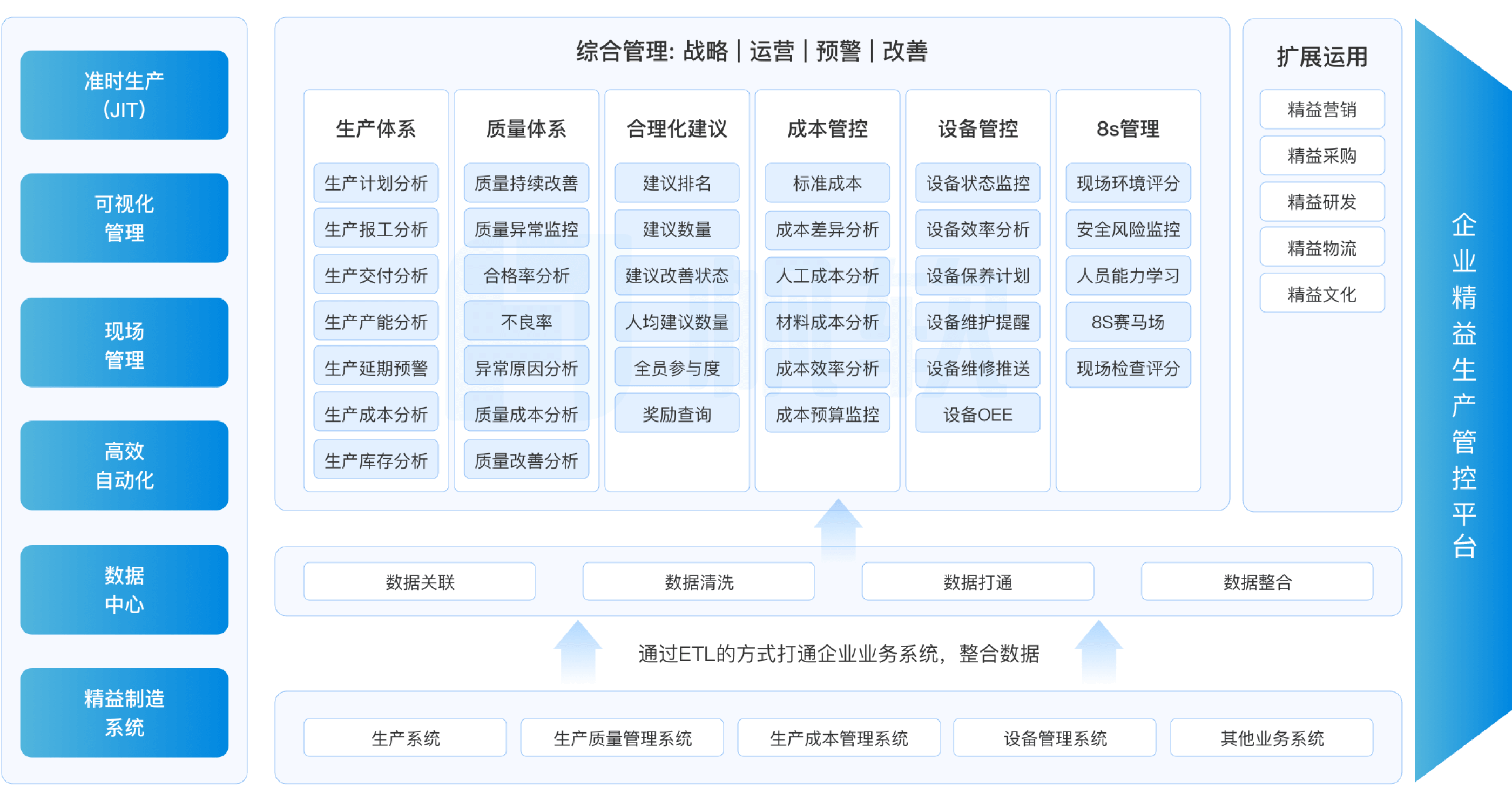

Key Components of Management Solutions

Several key components are designed to ensure process optimization, cost control, and quality assurance.

The intelligent production architecture flexibly supports various types of business operations.

Empowered by the intelligent architecture, it enables comprehensive monitoring and scheduling of the production process, thereby improving production efficiency, reducing costs, enhancing product quality, and supporting decision-making.

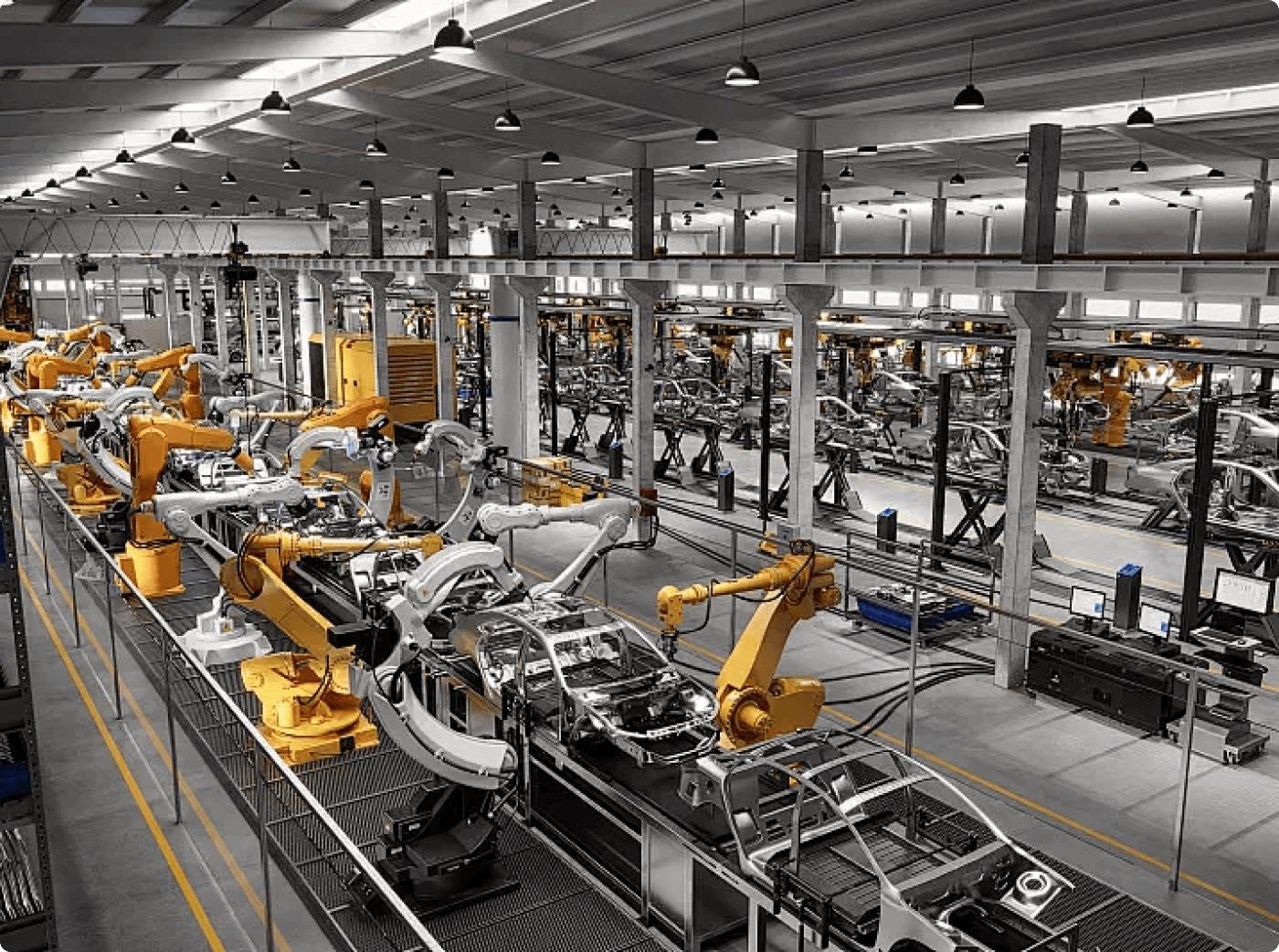

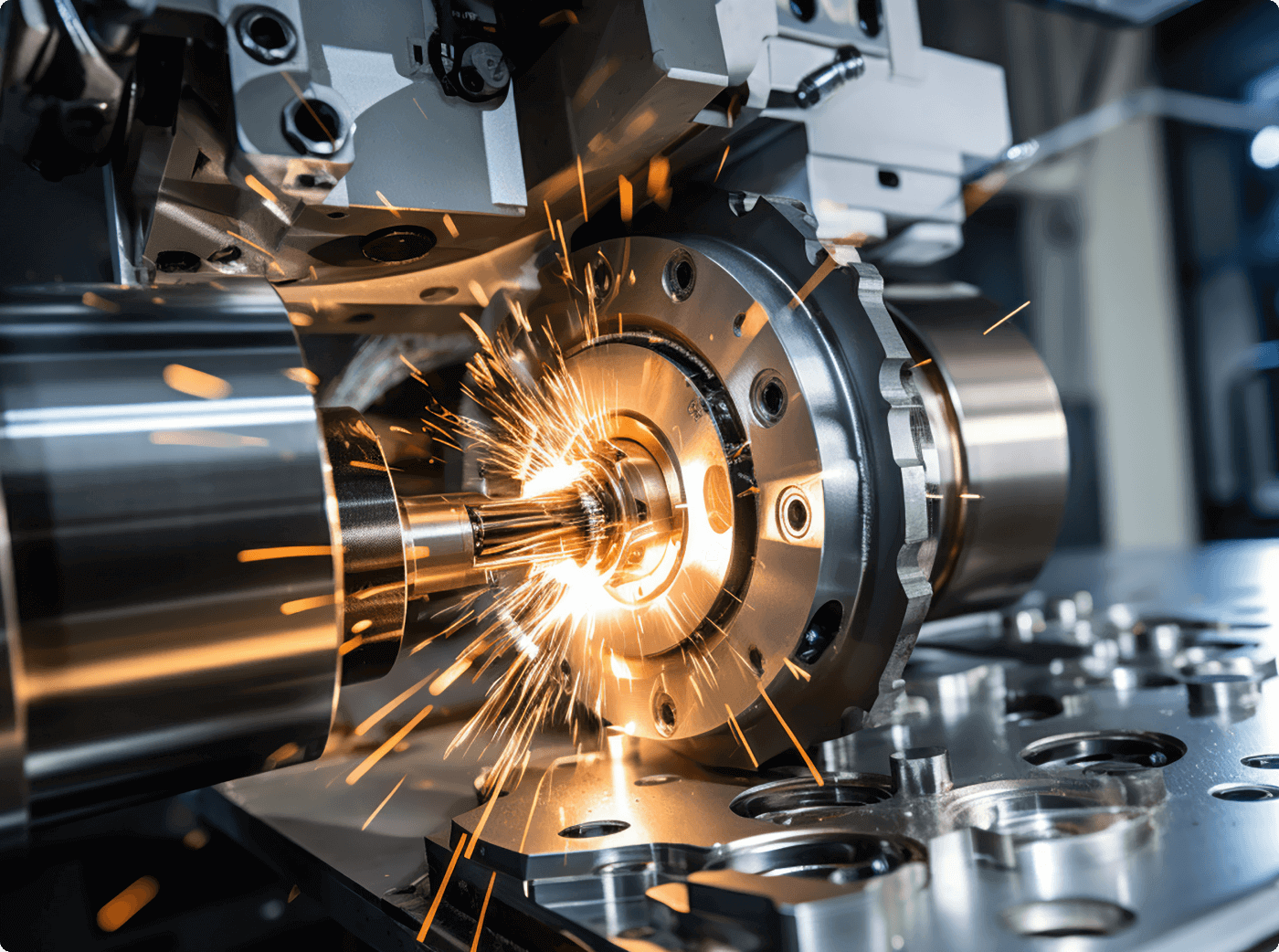

Application Scenarios

Through customized solutions, the production management system can meet the specific needs and challenges of particular industries.